In a remarkable stride forward for materials science, researchers have unveiled a suite of groundbreaking techniques that promise unprecedented control over the synthesis of nanomaterials. For decades, the quest to fabricate nanostructures with precise dimensions, compositions, and architectures has been a central challenge, limiting the full realization of their potential in electronics, medicine, energy, and beyond. The inherent difficulties of manipulating matter at the atomic and molecular scale have often resulted in batches of nanoparticles with inconsistent sizes or shapes, a critical flaw for applications requiring uniformity. However, the latest developments emerging from laboratories across the globe are not merely incremental improvements; they represent a paradigm shift in our approach to nanomaterial fabrication. Scientists are now demonstrating an ability to engineer nanoparticles with a level of precision once thought to be the realm of science fiction, moving from haphazard production to truly designed and predictable synthesis.

The cornerstone of this revolution is the refined application of colloidal synthesis methods, particularly advanced hydrothermal and solvothermal techniques. Where traditional methods struggled with reproducibility, new protocols involving meticulously controlled temperature gradients, pressure environments, and injection rates of precursors are yielding stunningly uniform results. For instance, a team at the Institute for Advanced Materials has published a paper detailing a continuous-flow reactor system that allows for real-time monitoring and adjustment of reaction parameters. This system can produce quantum dots with a size deviation of less than 2%, a feat previously unattainable on a scalable level. The secret lies in the sophisticated feedback loops that use spectroscopic data to instantly correct any drift in the reaction conditions, ensuring each nanoparticle nucleates and grows under near-identical circumstances.

Parallel to these advances in solution-based synthesis, vapor-phase deposition techniques have undergone a similar transformation. Chemical Vapor Deposition (CVD) and Atomic Layer Deposition (ALD) are no longer just tools for creating thin films. Through the introduction of novel precursor molecules and the precise spatial and temporal sequencing of their introduction, researchers can now build complex nanostructures layer by layer with atomic accuracy. A recent breakthrough from a joint European-American collaboration demonstrated the growth of hybrid metal-organic framework (MOF) nanostructures directly onto silicon wafers. This was achieved by programming the ALD chamber to alternate between metal-organic and purely organic precursors at specific intervals, effectively "writing" the desired structure with a chemical pen. This level of control opens the door to the direct integration of highly functional nanomaterials into existing semiconductor manufacturing processes.

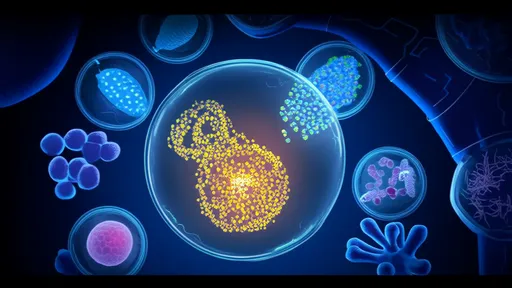

Perhaps the most futuristic of the new methods involves the use of DNA origami and biological templates. Inspired by nature's own nanomachines, scientists are leveraging the predictable base-pairing of DNA to create intricate scaffolds that can position atoms and molecules with sub-nanometer precision. In a landmark study, a group used a designed DNA framework to arrange gold atoms into a specific, non-naturally occurring crystalline structure. The DNA not only dictates the final shape but also acts as a catalyst and a constraint, guiding the synthesis process along a predetermined pathway. This bio-inspired approach is particularly powerful for creating asymmetric and chiral nanoparticles, which are highly sought after for advanced optical and catalytic applications but have been notoriously difficult to synthesize through conventional means.

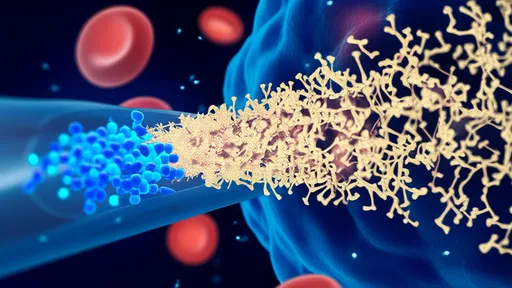

The implications of these synthetic leaps are profound and immediate. In the field of catalysis, the ability to craft nanoparticles with exact facet exposure—meaning scientists can control which crystal faces are on the surface—is leading to catalysts with orders-of-magnitude higher activity and selectivity. This could drastically improve the efficiency of industrial processes like ammonia synthesis or fuel cell operation, reducing energy consumption and waste. In medicine, the newfound precision allows for the design of nanocarriers whose size, shape, and surface chemistry are optimized for specific tasks: spherical particles for circulation, rod-shaped particles for tissue penetration, and particles with specific ligands for targeting diseased cells. This moves nanomedicine away from a one-size-fits-all approach towards truly personalized therapeutics.

Furthermore, the impact on quantum computing and electronics cannot be overstated. The performance of quantum bits (qubits) and other nanoscale electronic components is exquisitely sensitive to defects and variations in their structure. The controlled synthesis methods now enable the creation of arrays of identical semiconductor nanocrystals or superconducting nanoparticles, which is a fundamental requirement for building scalable quantum computers. For traditional electronics, it paves the way for next-generation transistors and memory devices that leverage the unique properties of nanomaterials without being hobbled by the inconsistency that has plagued previous integration attempts.

Despite the exhilarating progress, the scientific community acknowledges that challenges remain. Scaling these precise synthesis methods to industrial production volumes while maintaining cost-effectiveness is the next great hurdle. The sophisticated equipment and ultra-pure precursors required are currently expensive, and translating a successful lab protocol to a high-throughput factory setting is a non-trivial engineering task. However, the pace of innovation suggests these are surmountable obstacles. The field has moved from asking "Can we make this nanomaterial?" to "How can we make it perfectly, every single time?" This shift in mindset, coupled with these groundbreaking technical achievements, marks the dawn of a new era in nanotechnology—an era defined by control, design, and the limitless potential of materials built atom by atom.

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025