In the race against climate change, carbon capture technologies have emerged as a critical frontier in global efforts to reduce atmospheric CO2 levels. Among the most promising advancements in this field is the development of novel adsorbent materials designed to efficiently capture carbon dioxide from industrial emissions and even directly from the air. These materials represent a significant leap forward from traditional methods, offering higher selectivity, greater capacity, and reduced energy requirements for regeneration.

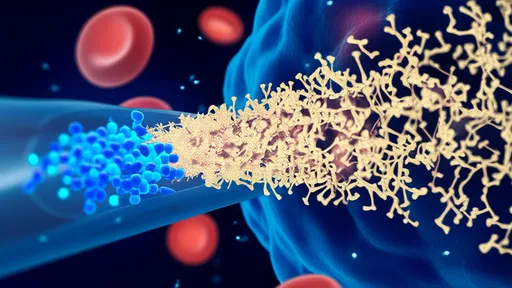

Recent breakthroughs in material science have led to the creation of several innovative adsorbents, including metal-organic frameworks (MOFs), porous polymer networks, and advanced carbon-based structures. MOFs, in particular, have garnered substantial attention due to their exceptionally high surface areas and tunable pore sizes, which allow researchers to tailor their properties for optimal CO2 adsorption. Laboratories worldwide are experimenting with various metal nodes and organic linkers to enhance the stability and capacity of these frameworks under real-world conditions.

Concurrently, researchers are developing novel porous organic polymers that demonstrate remarkable CO2 uptake capabilities even in the presence of moisture, a significant challenge for many traditional adsorbents. These hydrophobic materials maintain their structural integrity and performance in humid environments, making them particularly suitable for capturing carbon from flue gases where water vapor is prevalent. The versatility of these polymers allows for functionalization with amine groups, further boosting their affinity for carbon dioxide molecules.

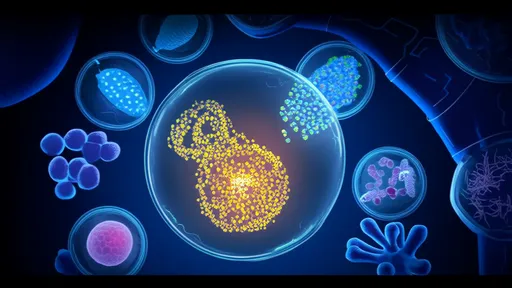

Testing these advanced materials involves rigorous laboratory experiments and increasingly sophisticated computational modeling. Scientists are employing breakthrough curve measurements, thermogravimetric analysis, and in-situ spectroscopy to evaluate adsorption capacity, kinetics, and selectivity. The most promising candidates undergo prolonged cycling tests to assess their stability through thousands of adsorption-desorption cycles, simulating years of operational use in industrial settings.

Beyond the laboratory, several pilot projects have begun testing these novel adsorbents at scale. A notable initiative in Scandinavia has implemented a MOF-based capture system at a waste-to-energy plant, where early results show capture efficiencies exceeding 90% with approximately 30% less energy penalty compared to conventional amine scrubbing. Similarly, a demonstration project in East Asia is testing temperature-swing adsorption using advanced carbon composites that can be regenerated using low-grade waste heat, potentially dramatically reducing operating costs.

The regeneration process remains a critical focus area, as the energy required to release captured CO2 significantly impacts the overall efficiency and economics of carbon capture systems. Researchers are developing materials that require less thermal energy for regeneration or respond to alternative stimuli such as pressure changes or electrical currents. Some of the most innovative approaches involve photoresponsive adsorbents that release CO2 when exposed to specific wavelengths of light, potentially enabling ultra-low energy regeneration cycles.

Despite these promising developments, challenges persist in scaling up production of these advanced materials while maintaining consistency and controlling costs. Manufacturing complex frameworks like MOFs at industrial scales requires innovative approaches to synthesis and purification. Several companies are developing continuous flow production methods that could potentially reduce costs by orders of magnitude, making these materials economically viable for widespread deployment.

The testing phase has revealed additional considerations beyond pure adsorption performance. Engineers are evaluating how these materials handle real flue gas compositions containing not just CO2 and water vapor, but also trace contaminants like sulfur oxides and nitrogen oxides that could potentially degrade adsorbent performance over time. Long-term durability testing under realistic conditions is essential for commercial adoption.

Looking ahead, the next generation of adsorbents is already taking shape in research laboratories. Multifunctional materials that can capture CO2 while simultaneously removing other pollutants are showing particular promise. Some teams are working on "smart" adsorbents that change color when saturated, providing visual indicators for regeneration timing. Others are developing materials that can capture carbon dioxide and convert it directly into useful products through integrated catalytic functions.

The development and testing of novel adsorbent materials for carbon capture represents one of the most dynamic and rapidly evolving areas of climate technology research. As these materials move from laboratory curiosities to commercial applications, they hold the potential to transform carbon capture from an expensive mitigation option into an economically viable climate solution. With continued research and investment, these advanced adsorbents could play a crucial role in achieving global carbon neutrality targets in the coming decades.

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025