The development of environmentally adaptive systems represents one of the most transformative frontiers in materials science and engineering. These systems, often built upon smart responsive materials, possess the ability to perceive external stimuli and react in a dynamic, functional manner. From architecture that breathes with climatic changes to medical implants that adjust to physiological conditions, the implications are profound and far-reaching. Researchers and industries alike are racing to harness these capabilities, aiming to create a new generation of technologies that seamlessly integrate with and adapt to their surroundings.

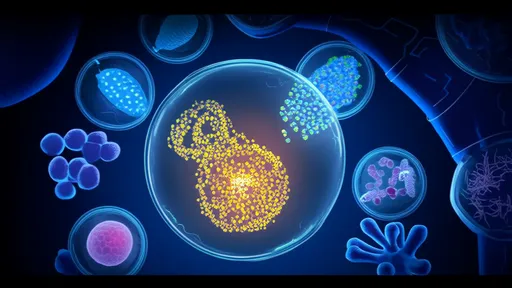

At the heart of these innovations lie smart materials—substances engineered to respond predictably to environmental triggers such as temperature, light, moisture, or mechanical stress. Shape-memory alloys, for instance, revert to their original form when heated, while hydrogels swell or shrink in response to pH changes. Such behaviors are not merely reactive; they are designed to be reversible and repeatable, enabling sustained adaptation over time. This functionality is often achieved through sophisticated molecular or structural design, where material composition and architecture are tailored to specific applications.

The drive toward environment-responsive systems is largely motivated by the growing demand for sustainability and efficiency. In construction, for example, facades embedded with thermochromic materials can modulate solar heat gain by changing color with temperature fluctuations, reducing reliance on energy-intensive heating and cooling systems. Similarly, self-healing concretes incorporate microcapsules that rupture upon crack formation, releasing agents that seal fractures and prolong structural life. These advancements not only enhance durability but also minimize resource consumption and waste.

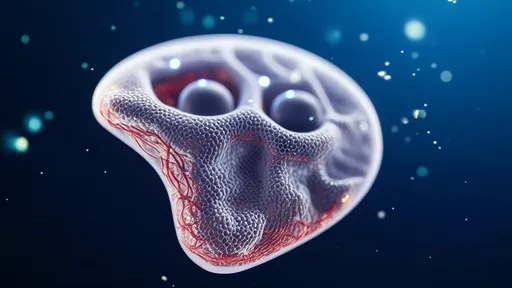

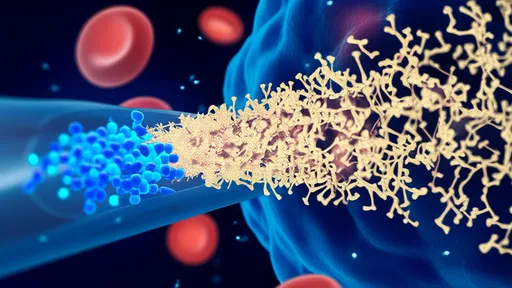

Beyond built environments, adaptive materials are making significant inroads in biomedical engineering. Implants and prosthetics fashioned from stimuli-responsive polymers can alter their shape or stiffness in response to bodily conditions, offering improved compatibility and patient outcomes. Drug delivery systems, too, are being revolutionized; capsules designed to release therapeutics in the presence of specific biomarkers enable targeted treatment with reduced side effects. Such precision was once the realm of science fiction but is now increasingly attainable through material innovation.

However, the path to widespread adoption is fraught with challenges. Scalability remains a critical hurdle, as laboratory successes often struggle to transition to industrial production. The synthesis of smart materials frequently involves complex processes and costly raw materials, limiting their economic viability. Moreover, ensuring long-term stability and performance under real-world conditions—amidst variability and unpredictability—requires rigorous testing and refinement. Researchers are actively exploring composite approaches and hybrid systems to overcome these barriers, combining multiple responsive elements to enhance functionality and robustness.

Interdisciplinary collaboration has emerged as a key enabler in this field. Chemists, physicists, biologists, and engineers are pooling expertise to decode the fundamental mechanisms driving material responses and to translate these insights into practical applications. Computational modeling, too, plays an increasingly vital role, allowing scientists to simulate material behavior under diverse scenarios and accelerate the design cycle. This synergy between theory, experiment, and application is fostering a more holistic and innovative approach to development.

Looking ahead, the potential applications of environmentally adaptive systems seem boundless. In agriculture, responsive polymers could be used to create soil coatings that regulate water retention based on humidity, combating drought conditions. In textiles, fabrics embedded with phase-change materials might adjust their insulation properties to keep wearers comfortable across varying climates. Even urban infrastructure could become more resilient; roads incorporating temperature-responsive additives might heal cracks during warm weather, reducing maintenance needs and improving safety.

Ethical and societal considerations also come into play. As these technologies become more pervasive, questions regarding privacy, security, and equity arise. For instance, adaptive surveillance materials that change properties in response to human presence might offer enhanced security but also raise concerns about monitoring and consent. Additionally, the accessibility of advanced adaptive systems must be addressed to prevent a divide between those who can benefit from them and those who cannot. Policymakers and developers must work together to establish frameworks that ensure responsible and inclusive innovation.

The journey toward truly intelligent, environment-integrated systems is still in its early stages, but progress is accelerating. With each breakthrough, we move closer to a world where materials and structures are not static entities but dynamic partners in addressing human and planetary challenges. The convergence of smart materials with digital technologies like the Internet of Things and artificial intelligence promises even greater capabilities, enabling systems that not only adapt to their environment but also learn from it and anticipate future needs.

In conclusion, the development of smart responsive materials and environmentally adaptive systems is reshaping our interaction with the world. These advancements hold the promise of more sustainable, efficient, and responsive solutions across sectors. While obstacles remain, the collaborative and innovative spirit driving this field suggests a future where our materials are not just used by us—but work with us.

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025